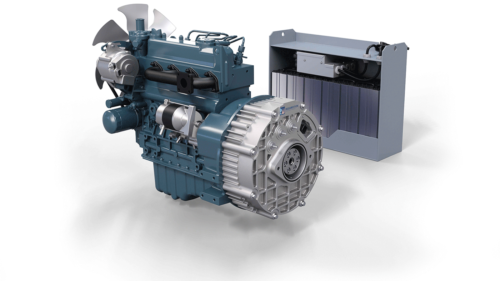

Power Assist Hybrid is a complete solution for hybrid propulsion. The main components of a Power Assist Hybrid are the battery pack, an electric motor/generator, and a sophisticated control system.

An efficient PMAC motor mounts directly to the combustion engine in a so called P1 or P2 hybrid architecture, with or without a clutch. Different machines will require different control strategies, and the hybrid control system is flexible enough to meet most application needs.

Seamless

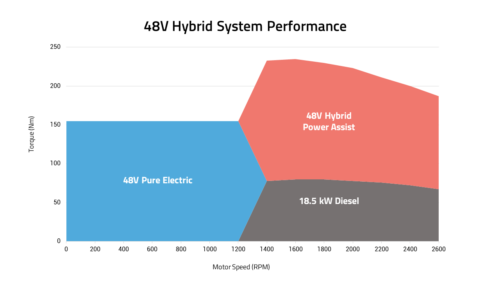

One typical use case for the system is the 48V Mild Hybrid, where the system automatically adds electric power when needed during peak loads and recharges the batteries in between. Thanks to the instantaneous torque and power response of the electric motor, this solution provides an excellent operator experience.

Full or Mild Hybrid

The system can be tailored to other specific needs. An added clutch between the combustion engine and the motor allows for fully electric drive inside buildings or other emission-restricted areas. Increasing the size of the battery allows for a plug-in hybrid strategy, which drastically decreases the fuel consumption of the machine.

In some cases, the battery does not have to power the propulsion of the vehicle at all. Instead, auxiliary functions that are traditionally powered by the combustion engine through hydraulics or mechanically can be replaced by electric counterparts with higher efficiency that only run on-demand.

Stage V Friendly

The intermittent duty cycles that are common for non-road mobile machinery (NRMM) are not ideal for the aftertreatment equipment needed today, such as DPF and SCR. Downsizing the engine and adding a hybrid system allows the aftertreatment equipment to operate in a more beneficial way. Downsizing below 19 kW eliminates the need for DPF altogether. In many cases, this is possible for machines that currently use engines up to 35 kW.

- Our trademark Regamotion® covers electric drive systems for mobile machinery and electric vehicles.

- Read more about our electric drive components used in our systems: Components

- Please contact us for further help and support. We will find the right product and service solution for your application!